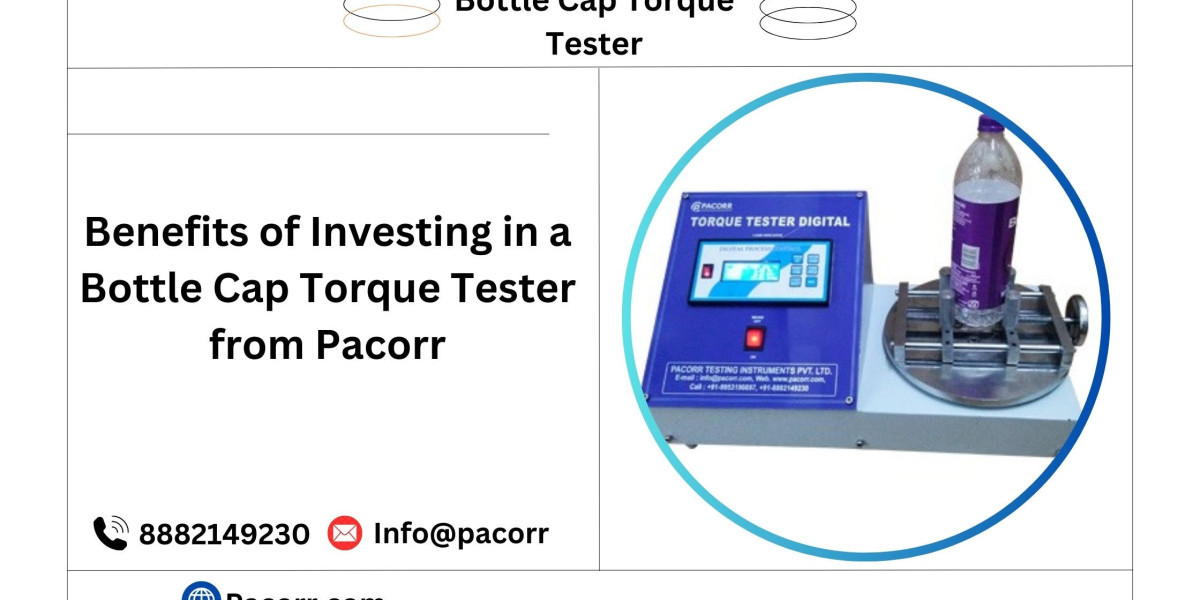

At Pacorr.com, we specialize in providing cutting-edge bottle cap torque testers designed to meet the unique needs of manufacturers worldwide.

What Is a Bottle Cap Torque Tester?

A bottle cap torque tester is a precision instrument used to measure the force required to apply or remove a cap from a bottle. Torque refers to the rotational force that ensures the cap is securely fastened while maintaining ease of opening for the end-user.

Improper torque settings can lead to significant issues:

- Under-torquing: Caps may be too loose, leading to leaks, contamination, or product spoilage.

- Over-torquing: Caps may become excessively tight, causing damage to the cap, bottle, or seal and creating challenges for consumers.

A bottle cap torque tester ensures optimal torque, preserving product safety and enhancing user experience.

Why Is Torque Testing Essential?

Proper torque application isn’t just a technical requirement—it’s a fundamental aspect of packaging quality. Here’s why torque testing is essential for manufacturers:

- Leak Prevention: Correctly applied torque ensures that the cap forms an airtight seal, preventing leaks and maintaining product freshness.

- Product Integrity: For sensitive products like pharmaceuticals, proper sealing is critical to ensure efficacy and compliance with regulatory standards.

- Consumer Convenience: Overly tight caps can frustrate customers, while loose caps can create distrust in product quality.

- Regulatory Compliance: Many industries have strict packaging guidelines. Torque testing helps manufacturers meet these standards.

- Consistency: A torque tester ensures uniformity across production batches, reducing waste and maintaining brand reputation.

Types of Bottle Cap Torque Testers

Bottle cap torque testers are available in various designs, catering to diverse industrial requirements. Here are the main types:

Manual Torque Testers

- Operated by hand and suitable for low-volume production or laboratory testing.

- Cost-effective and easy to use.

- Ideal for smaller operations or research and development purposes.

Digital Torque Testers

- Equipped with advanced sensors for precise, real-time torque measurements.

- Features a digital display for easy reading.

- Provides high accuracy and repeatability, making them perfect for industries with stringent quality standards.

Automated Torque Testers

- Designed for high-speed production lines.

- Fully automated to ensure consistent and accurate torque testing without manual intervention.

- Ideal for large-scale manufacturers.

Tabletop Torque Testers

- Compact and versatile, making them a popular choice for laboratories and small-scale production.

- Easy to set up and operate, with options for manual or digital operation.

Key Features of Advanced Bottle Cap Torque Testers

Modern torque testers come equipped with features that make them indispensable for packaging operations:

- High Accuracy Sensors: Deliver precise torque readings to ensure quality control.

- Adjustable Clamps: Accommodate bottles of varying sizes, shapes, and materials.

- Digital Displays: Provide clear and easy-to-read torque values.

- Data Logging: Store and retrieve test results for analysis and reporting.

- Connectivity Options: Many testers integrate with computers or data management systems for advanced analytics.

- Durable Build: Designed to withstand rigorous use in industrial environments.

Industries That Rely on Bottle Cap Torque Testers

A wide range of industries benefits from using torque testers, including:

Beverages

- Ensures caps are sealed tightly to prevent leaks and maintain carbonation.

- Facilitates compliance with food safety regulations.

Pharmaceuticals

- Guarantees child-resistant and tamper-evident closures meet strict regulatory requirements.

- Protects sensitive formulations from contamination.

Cosmetics

- Verifies the sealing of liquid or cream-based products to maintain quality and avoid spillage during transport.

Food Packaging

- Prevents spoilage by ensuring airtight seals on jars and bottles.

Chemical Industry

- Ensures safety by preventing leaks of potentially hazardous substances.

Benefits of Using Bottle Cap Torque Testers

- Enhanced Product Quality: Ensures caps are applied with the correct torque, enhancing safety and usability.

- Cost Efficiency: Reduces material waste and production downtime caused by defective sealing.

- Improved Brand Reputation: Consistent, reliable packaging builds trust with consumers.

- Regulatory Compliance: Meets industry standards and avoids penalties or recalls.

- Streamlined Operations: Automated or digital testers improve productivity and reduce manual labor.

Why Choose Pacorr.com for Bottle Cap Torque Testers?

At Pacorr.com, we pride ourselves on delivering high-quality testing solutions tailored to your needs. Here’s what sets us apart:

- Wide Product Range: We offer an extensive selection of torque testers, from manual to fully automated models.

- Uncompromising Quality: All our products are designed to meet international quality standards, ensuring reliability and durability.

- Expert Guidance: Our team of professionals helps you select the right tester for your specific requirements.

- Competitive Pricing: Affordable solutions without compromising on quality.

- After-Sales Support: Comprehensive service, including installation, calibration, and maintenance.

How to Maintain Your Bottle Cap Torque Tester

Proper maintenance ensures your torque tester operates efficiently for years to come. Here are some tips:

- Regular Calibration: Schedule periodic calibration to maintain measurement accuracy.

- Cleanliness: Keep the device free from dust and debris.

- Inspect Components: Check clamps, sensors, and displays regularly for wear and tear.

- Update Software: For digital testers, ensure firmware and software are up to date.

- Professional Servicing: Rely on authorized service providers for repairs and maintenance.

Conclusion

A bottle cap torque tester price is more than just a tool—it’s a guarantee of quality, safety, and customer satisfaction. For businesses in industries like beverages, pharmaceuticals, cosmetics, and food, torque testing is an essential part of the production process. By ensuring proper torque application, you not only enhance product integrity but also build trust with your consumers.

At Pacorr.com, we offer premium torque testing solutions tailored to your needs. With our expertise, you can streamline your operations, ensure compliance, and deliver superior products to your customers. Don’t settle for less—explore our range of bottle cap torque testers and experience the Pacorr difference.

? Visit us today at Pacorr.com to learn more! Your packaging quality deserves the best.